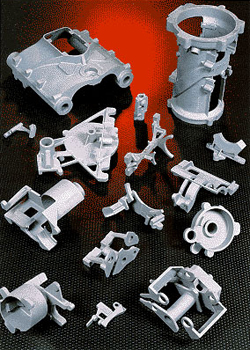

Investment Castings

Metal mold makes wax or plastic replica. These are sprued, then surrounded with investment material, baked out, and metal is poured in the resultant cavity. Molds are broken to remove the castings.

Metals:

Most castable metals.

Size Range:

Fraction of an ounce to 150 lbs.

Tolerances:

± .003″ to 1/4″

± .004″ to 1/2″

± .005″ per inch to 3″

± .003″ for each additional inch.

Surface Finish:

63-125RMS

Minimum Draft Requirements:

None

Normal Minimum Section Thickness:

.030″ (Small Areas)

.060″ (Larger Areas)

Ordering Quantities:

Aluminum: usually under 1,000.

Other metals: all quantities.

Normal Lead Time:

Samples: 5-16 weeks (depending on complexity)

Production:

4-12 weeks A.S.A. (depending on subsequent operations).